Chemflow Products, LLC provide complete hose assembly services:

Fittings:

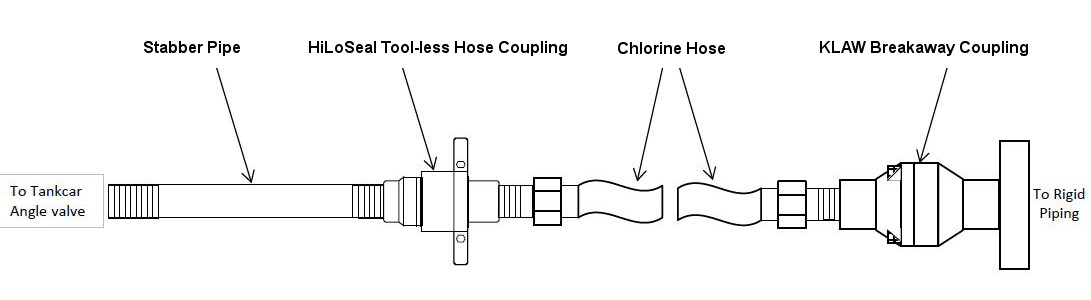

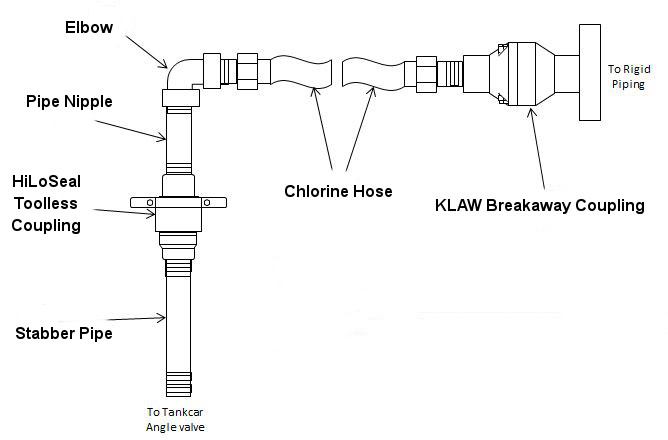

HiLoSeal Tool-less Hose Couplings

Pipe Nipples

Elbows / 45’s, 90,s

KLAW KD Breakaway Couplings

Cleaning:

Ultrasonic Cleaning or Cl2 Compatible Solvent Cleaning of all components.

Assembly:

Screwed or Welded

PTFE Teflon Tape with LOX-8 Paste thread sealant used on all threaded connections.

Testing:

250 psi dry nitrogen pressure soak for 30 minutes.

Documentation:

All assembly and testing is documented for each order.

Hose Choices:

Hose Master ChlorSafe™ Chlorine Transfer hose features 100% Hastelloy C276 Construction for use in Wet or Dry Chlorine Applications. Service life of up to 2 years.

Hose Master ChlorSafe™ Chlorine Transfer hose features 100% Hastelloy C276 Construction for use in Wet or Dry Chlorine Applications. Service life of up to 2 years.

St. Gobain Versilon™ Chlorine Transfer Hose Assemblies feature PTFE Fluoropolymer Helically Convoluted Inner Tubes with Double PVDF (Kynar®) Braids for strength and pressure rating. An outer scuff guard of PVDF braid provides protection for the hose assembly. End fittings in Monel, PVDF or Hastelloy C are available w/ NPT or 300# Flanged Ends.

Available in 1/2″, 1″ and 1-1/2″ diameters, and lengths to 50′.

Feel free to contact CHEMFLOW for any questions, or e-mail us at info@honeywellcontrols.com. Follow us on LinkedIn.